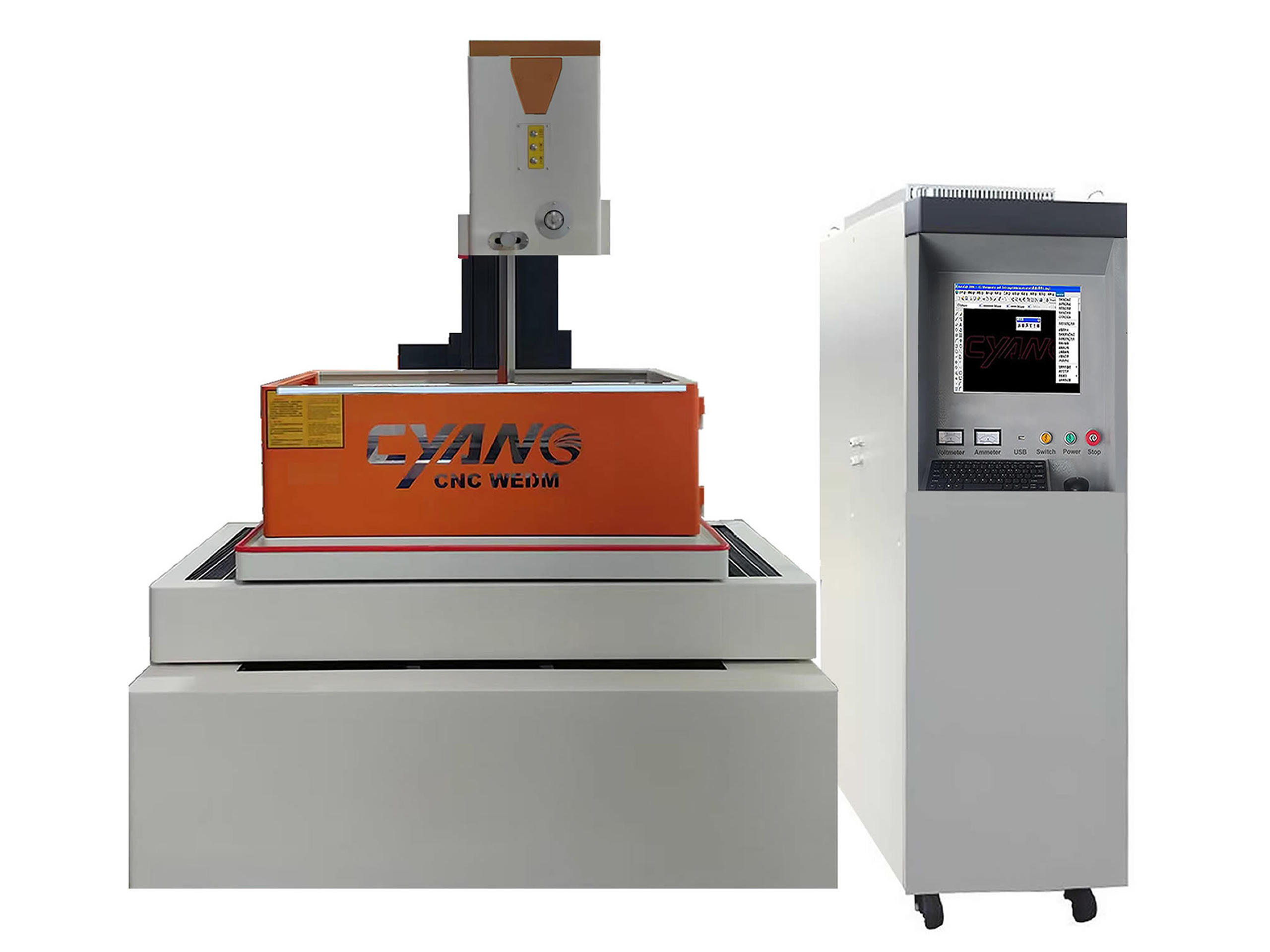

Multiple cut Precision Wire Cutting Machine

Multiple cutting Medium speed wire cut EDM is a new generation of EDM machines . With Multi-cutting functions (and low-speed Brass wire cutting machine works the same principle), the quality of processing also tends to low-speed brass wire cutting machine, but the cost is only 1/10 of the low-speed brass wire wire cutting machine is the most cost-effective model.This type is popular machines. The machine is driven by stepping motor or AC servo motor, Affordable prices.

INTELLIGENT CNC SYSTEM

①This new designed Autocut software is the unique software for WEDM running on the condition of windows . It is use graphic drive technology and auto-program, user doesn’t need to contact the code, only need to set the processing technics for the graphic. meanwhile,support 3B and G code generated by other WEDM software.upgrade the efficiency of working, reduce the mistakes.

② Adopt High Performance Industrial computer, P4 or better, 4G RAM, 1000G Harddisk, support INTERNET, with 17"LED Color Monitor.

③To achieve a fast and convenient computer communication network, through network technology, graphics, data and program transmission, can be directly controlled by the technical design department since the first establishment of a program.

⑤Embedded Control system can be smoothly connected with many design software such as AUTOCAD & etc. Fulfill integration of CAD/CAM.

⑥Adopt 4 axes linkage control technic to process taper workpiece. Process the top and bottom shaped taper conveniently, make the complicated processing easy and exactly.Process track with 3D designed.

⑦XY axis the drive motor be set at AC servo motor. The search function of mechanical origin enable the transmission screw pitch compensation, in order to greatly improve the positioning accuracy.

⑨With a large storage capacity database, which accumulated from many experiences. User can choose the suitable parameter according to deferent working conditions. Users can adjust machining parameters to establish a database at any time according to their own experience.

⑩Pulse power of the control parameters directly from the software to control and improve the ability of pulsed power output of the interference, thereby increasing the roughness of workpiece, reducing the loss of molybdenum wire, you can choose a variety of pulse waveforms for a variety of processing conditions, improve the cutting ability of the workpiece. Simplifies the operation buttons on the control panel, a large number of button functions directly controlled by software to achieve.

Product parameters

Machine body | MS-430AC | MS-540AC | MS-650AC | MS-860AC | MS-1080AC |

Worktable stroke(X,Y,Z) | 400×320×300mm | 500×400×300mm | 600×500×400mm | 800×600×400mm | 800×1000×400mm |

Worktable size (W×D) | 780×630mm | 880×670mm | 1100×780mm | 1210×880mm | 1500×1050mm |

The oil tank size (W*D*H) | 920×680×400mm | 1020×720×400mm | 1240×830×400mm | 1350×930×400mm | 1650×1100×400mm |

Travel U、V | 70×70mm | 70×70mm | 70×70mm | 70×70mm | 70×70mm |

Max. taper angle / plate thickness | 6-12 degree / 80mm | 6-12 degree / 80mm | 6-12 degree / 80mm | 6-12 degree / 80mm | 6-12 degree / 80mm |

Max. cutting thickness | 300mm | 300mm | 300mm | 400mm | 400mm |

Max. workpiece weight | 400kg | 500kg | 650kg | 1000kg | 1000kg |

Max. workpiece dimension | 750×550×300mm | 850×600×300mm | 1050×700×400mm | 1200×800×400mm | 1510×970×400mm |

Wire Speed | 1.18-11.18m/s |

Diameter of wire | Dia.0.16~0.22mm |

Wire tension | 10-30N |

Positioning accuracy | ±0.008mm(ISO14137-2015,JB-T 11999.1-2014) |

Repeatable accuracy | ±0.005mm(ISO14137-2015,JB-T 11999.1-2014) |

Precision machining | Octagon±0.006mm(JB-T 11999.1-2014)Taper±0.03mm(JB-T 11999.1-2014) |

Machine dimension (W×D×H) | 1650×1250×2100mm | 1700×1400×2100mm | 2050×1680×2100mm | 2200×1960×2300mm | 2500×2000×2300mm |

Machine weight | 1650Kg | 1850Kg | 2200Kg | 2900Kg | 3500Kg |

Water tank |

Working liquid box dimension | 130L/870×470×320mm |

Working Methode | Filtration System |

Filter accuracy | 0.01mm |

Working liquid | Water-Soluble WEDM Concentrate |

Pulse Power |

Control box dimension | 580x580x1890mm |

Control box weight | 140kg |

Max. Cutting Currrent | 10A |

Max cutting speed | ≥150-300mm²/min(it is different for different material and thickness) |

Best Surface Finish | Ra≤0.85-1.6μm(it is different for different material and thickness) |

CNC System |

Operating system (OS); | Windows 7 & Windows 10 |

CNC Control system | Autocut |

Drawing Programming system | NCCAD,AutoCAD |

Hardware Configurations | Asus computer(8GB RAM, 1TB HDD), 17”LCD display, Yaskawa AC servo driver system |

Control method and axis | 4 axis Control simultaneous program |

Single pulse advancing accuracy | 0.001mm |

Data Port | USB, LAN |

Programming Code | 3B/ ISO/G code |

Menu Language | Chinese/English/Russian/Japanese |

Dimension | Metric/Inch |

Power Supply |

Rated Voltage | AC~,3N,380V±10% ,50/60Hz |

Other Voltage | 220V/415V |

Ratde Power | 2.5KVA |

Working temperature | 5-40℃ |

Relative humidity | 40%~80% |

管理员

该内容暂无评论